Ceramic Ball Mill

Product Details:

- Product Type Ball Mill

- General Use grinding

- Material Galvanized Steel

- Type Feed Grinding Machine

- Click to View more

Ceramic Ball Mill Price And Quantity

- 1 Unit

- USD ($)

Ceramic Ball Mill Product Specifications

- grinding

- Ball Mill

- Feed Grinding Machine

- Galvanized Steel

Ceramic Ball Mill Trade Information

- Shanghai

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 1000 Unit Per Month

- 15 Days

- Wooden Box Packing.

- CE & ISO 9001:2008

Product Description

Ceramic Ball Mill

Raw materials quartz feldspar barite calcite carbonate limestone talc ceramic iron ore carborundum bauxite rock phosphate coal and other materials total about 400 kinds of materials

Capacity 20200th

Max feeding size 25mm

Application suitable for processing various nonflammable and nonexplosive mineral materials with Mohs hardness less than 93 and humidity less than 6 it is widely used in the fields of metallurgy construction chemical industry mining highway construction etc

Shipping ports Shanghai China

Delivery 15 days after received the deposit

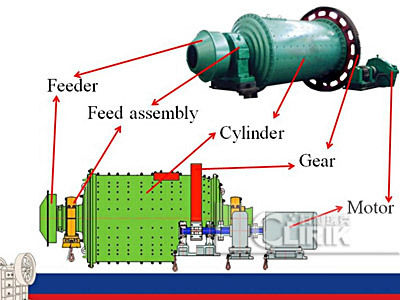

Ceramic Ball Mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials

Ceramic Ball Mill machine changes the intrinsic grinding mill structure Its body and ground plank are an integral whole So when fixing it can be lowered on a plane surface once only Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30 The intrinsic grille pattern forcing evacuation is instead by over fall pattern controlling one This can improve the milling of the granule and the quantity dealt with is reduced by 1520

Ceramic Ball Mill is a horizontal rotating device transmitted by the outer gear The materials are transferred to the grinding chamber through the quill shaft uniformly There are ladder liner and ripple liner and different specifications of steel balls in the chamber The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials The ground materials are discharged through the discharging board thus the grinding process is finished

Features of Ball Grinding Mill

Suitable for grinding material with high hardness

The shape of the final products is circular

No pollution for the powder with ceramic ball

Stable performance

Easy installation

The capacity and fineness can be adjusted by adjusting the diameter of the ball